The comprehensive evaluation of thermoelectric subcooling

solution combined with the state-of-the-art

ejector-based refrigeration cycle for food chain reduction

solution combined with the state-of-the-art

ejector-based refrigeration cycle for food chain reduction

Contract number: |

20214/43/D/ST8/02631 |

Total budget: |

706 990,00 PLN |

The SubCoolJet project is financed by the National Science Centre of Poland within SONATA-17 programme and its number is 2021/43/D/ST8/02631. It is carried out in a close cooperation with University Jaume I in Castellón de la Plana, Spain, and Public University of Navarra in Pamplona, Spain.

The objective of the project:

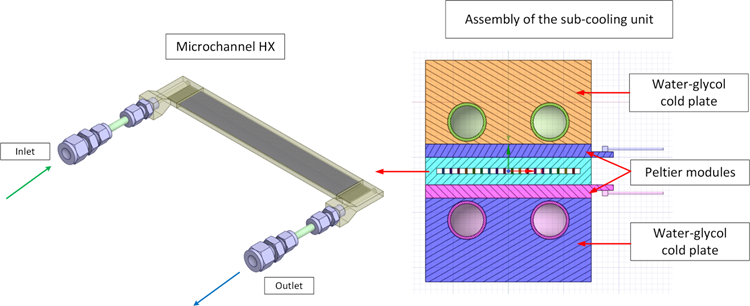

Minimizing losses in the food chain is essential to reduce the global and local problem of food waste. This design goal is especially important during phasing out of synthetic refrigerants and introducing low-impact working fluids into all refrigeration systems. For this reason, the aim of SubCoolJet is investigate the flow behaviour, the thermodynamic and the heat transfer effects of the thermoelectric sub-cooling solution integration together with the ejector-based refrigeration cycle using of environmentally friendly natural working fluids for food chain reduction. The liquid sub-cooling process of the refrigerant inside the vapour compression cycle using thermoelectric modules (TEM), such as the Peltier modules, allows for smooth capacity control and significant energy performance improvement of the state-of–the-art ejector-based cycles.

Research motivation:

The global awareness related to the global warming impact on the environment and climate change forces all of us to find new effective solutions and significantly improve the environment impact of each sector. The recent regulations regarding the phase-out of all fluorocarbon (FC), chlorofluorocarbon (CFC) and hydrochlorofluorocarbon (HCFC) based refrigerants phase-out from the market resulting in most hydrofluorocarbons (HFC) are difficult to apply or banned in Europe. Therefore, the only safe and necessary solution in the food industry and to reduce losses in the food chain is to use natural refrigerants, i.e., R744 and hydrocarbons either a pure single working fluid or mixture between them due to thermodynamic properties, availability and no negative impact on the environment. Although to maintain a high system energy performance (COP) in low- and high-temperature areas, it is required to use state-of-the-art technologies in the refrigeration system, which can be done by an integration of the ejector technology together with the thermoelectric sub-cooling solution.

A principal idea is to integrate thermoelectric sub-cooling unit together with the ejector-based refrigeration cycle using natural-based refrigerants, which will be never phased-out due to the negative impact to the environment. The main aim of the ejector in such a vapour compression rack is to recover an expansion work that results in higher efficiency of the whole system (even by 25%) and reduce the pressure ratio in the compressor resulting lower total power consumption. The benefits of the sub-cooling solution integration together with ejector-based refrigeration for natural-based working fluids can be defined as follows: (a) energy performance improvement for cooling (2°C÷8°C), low-temperature freezing (up to -25°C), and ultra-low temperature freezing (below -25°C) processes; (b) energy performance improvement for heating process, e.g. heat pumps and food dehydration; (c) cooling and heating capacities control of the fixed-type ejector for system optimisation at small, medium, and large-scales of refrigeration units; (d) operational envelope extension due to the flooded evaporator and R744-R1270 binary mixture, especially at low-freezing and ultra-low freezing processes; (e) a use of the unlimited natural-based working fluids with no impact on the global warming effect, ozone depletion process, human health, and the ground water poisoning.

According to the literature review, the combined solution of the ejector technology together with the sub-cooling TEM solution was investigated based only on the theoretical analysis. However, both solutions used for R744 let to improve system COP even by 39% for food storage process at high ambient temperature above 40°C [14]. Therefore, the integration of TEMs with the ejector technology allows for high COP improvement maintenance, optimum system control, and system compactness, which has to be deeply investigated using advanced numerical and experimental investigations that is in line with the environment protection policy.

Project description:

The project will be performed through the numerical simulation and experimental research. The project work plan is divided into four research tasks:

- Development of the computational fluid dynamics approach of the liquid sub-cooling process coupled with the 1-D electromagnetic numerical model of the Peltier module,

- Experimental analysis of the liquid sub-cooling solution work inside the CO2 (R744) ejector-based supermarket refrigeration unit for food freezing,

- Experimental investigation of the propane (R290) ejector-based small-scale heat pump unit capacity control using liquid sub-cooling solution,

- Experimental analysis of the sub-cooling ejector-based refrigeration unit using natural working fluids blends CO2 and propylene (R1270) for performance improvement at small-scale solutions.

Link to project home page:  Read more....

Read more....