Experimental and numerical investigation

– Research project objectives/Research hypothesis

The main scientific objective of the proposed project is to extend knowledge about structure of transcritical flow and mixing process of R744 (CO2) refrigerant, which is an natural alternative to hydrofluorocarbons (HFCs). These phenomena occur in all the most modern ejector-based air-conditioning systems, heat pumps as well as refrigeration units. Thanks to the use of the ejector, it is possible to recover some of the work lost irretrievably in the throttling valve in a traditional refrigeration system. This noticeably affects the energy efficiency of the entire vapour compression unit. Although, the ejector performance is strongly related to the cooling demand as well as to the ambient conditions, thereby the better understanding of the flow behaviour inside the ejector is needed.

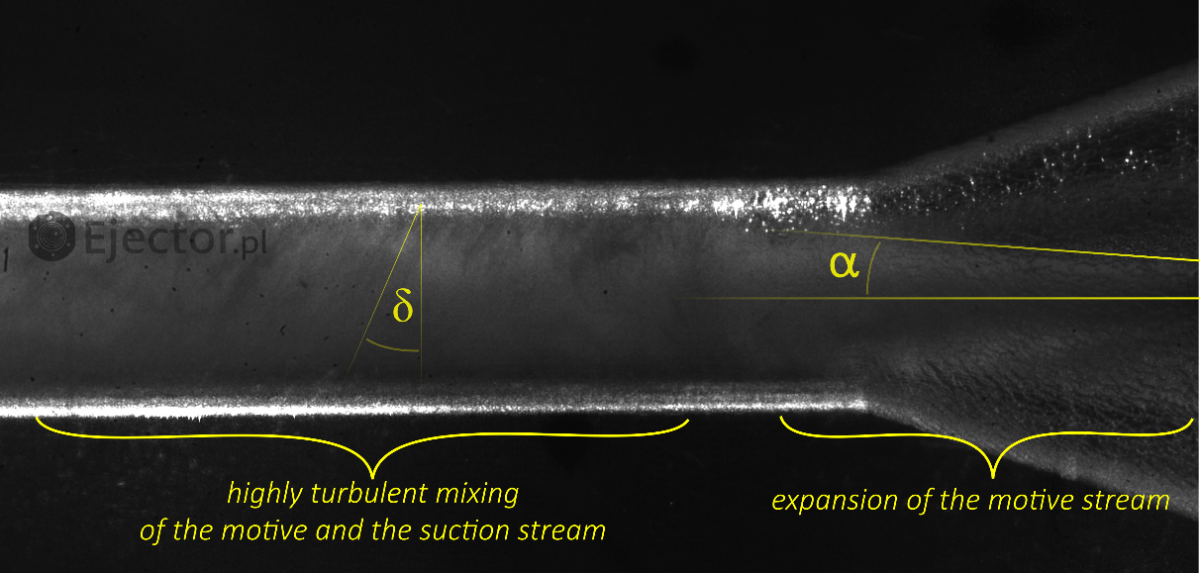

The most important element of novelty and progress in the proposed research is the measurement of local flow parameters, visualisation and development of experimentally validated CFD and reduced models of the mixing process of natural refrigerant inside the transcritical ejector. All this should lead to better understanding of those two-phase phenomena and enhancement of the ejector designs for all climate ambient conditions and future applications.

– Research project methodology

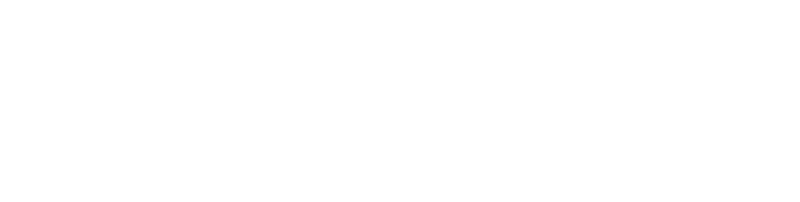

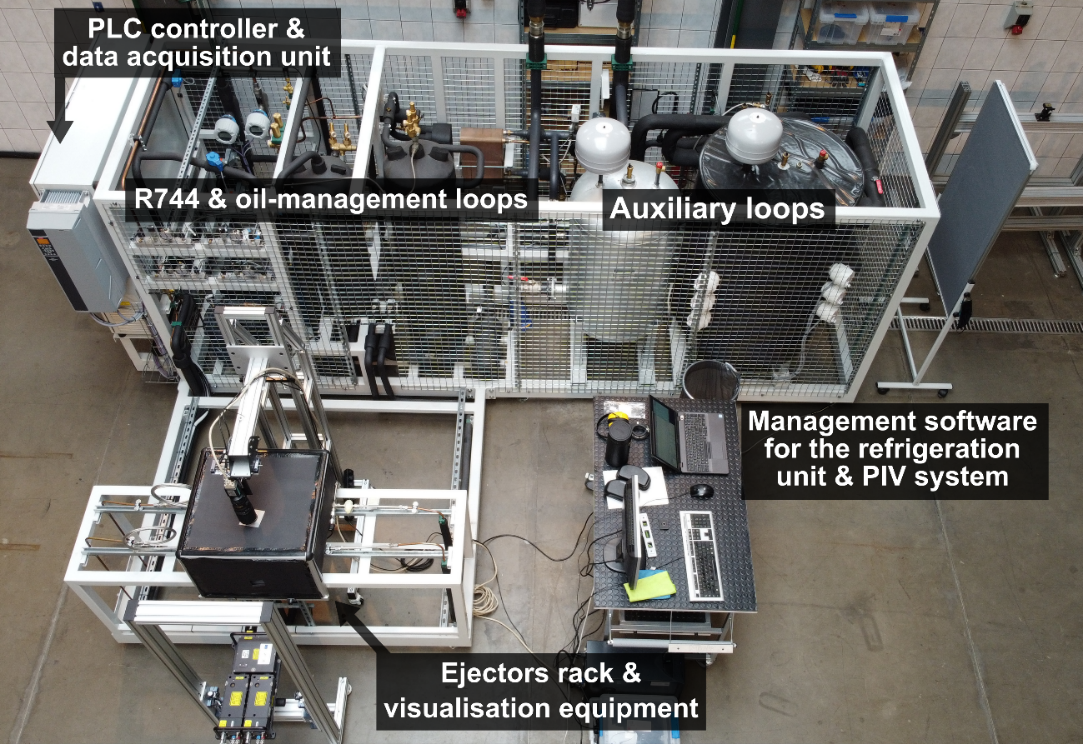

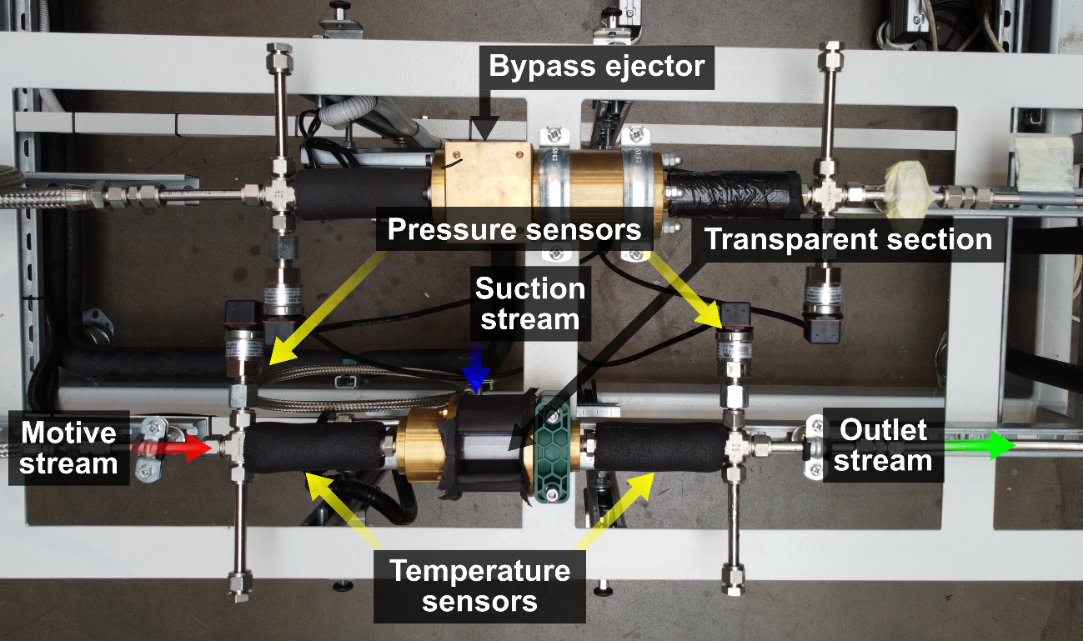

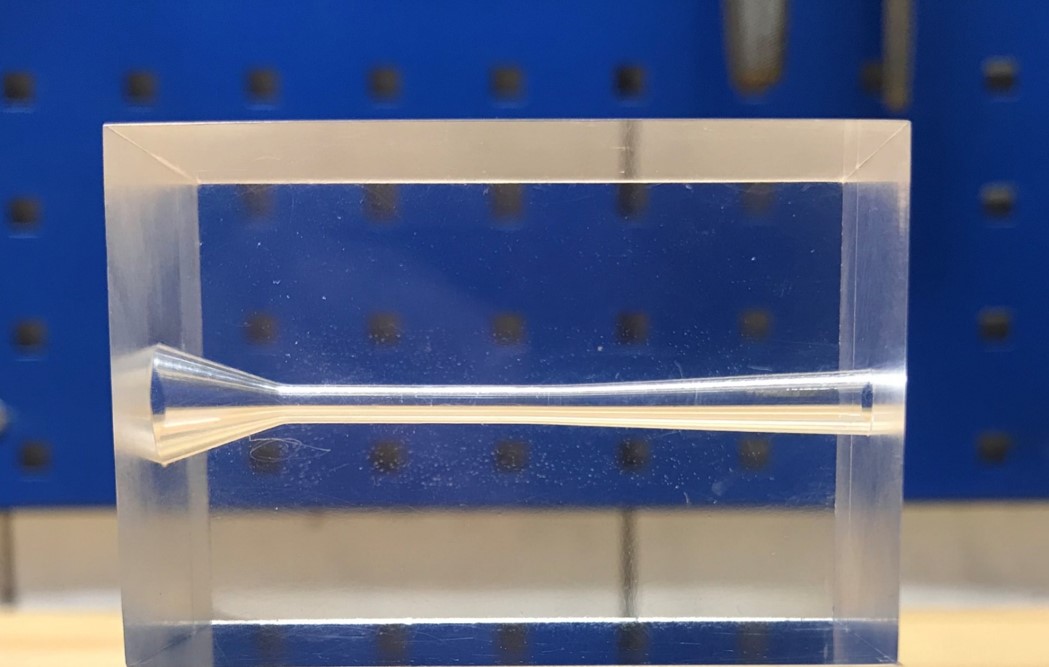

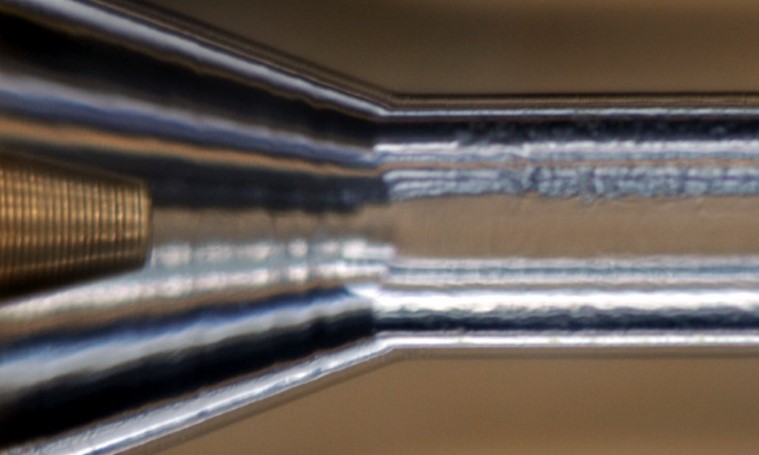

In the proposed project, special compression test rig will be designed and built to study and visualise the trans-critical flow of R744 through an ejector. In particular, the installation will enable recording of basic thermodynamic cycle parameters, i.e. inlet and outlet mass flow rates for all individual devices, pressures and temperatures. Transparent window/walls of the ejector having a rectangular cross-section will allow to visualise the flow structure of the R744 motive and suction streams and their mixing process. The most important part of the research will be the visualisation and registration using the high-speed camera of R744 flow and mixing processes inside the ejector. Additionally, an attempt will be made to measure local flow parameters inside the ejector, i.e. velocity field using the high-resolution Particle Image Velocimetry (PIV) system.

The studied phenomena will also be a subject of mathematical modelling using ejectorPL platform and the obtained computational results will be compared with the measurement records. Any differences between those results will be used to tune the mathematical models. In particular, models of turbulence from the RANS group as well as a more accurate LES model will be extensively tested. As for the flow models, homogeneous equilibrium (HEM) and relaxation (HRM) models will be analysed, but the non-equilibrium flow model of R744 inside the ejector will be considered as well.

The implementation of the project was divided into three main work packages (WPs). Each work package contains elements of novelty, which makes the entire project innovative. The originality in the WP1 package includes a new, specially developed reduced model for the designed ejector, which will then be used in the system analysis of the entire installation. WP2 can be seen as an unique approach to visualisation and measurement of local flow parameters inside the R744 ejector. In WP3, the numerical model of the natural refrigerant mixing processes inside the ejector will be fully validated based on local values of the flow parameters.

– Expected impact of the research project on the development of science

The proposed project will provide much more valuable data for understanding the flow and mixing processes of R744 than can currently be found in the available literature. Its positive result is widely expected by all the researchers working on the computer models of processes occurring in the R744 ejector, but also by engineers and designers involved in the system analysis and designing of the complete refrigeration cycles for this working fluid. Only a clear understanding of the two-phase flow and mixing phenomena together with computer model of these phenomena but fully validated experimentally (taking into account not only global flow parameters, but also local parameters), may bring in the future new solutions. Those should lead to reduction of the work lost during expansion inside the ejector and to significant improvement of its energy efficiency, and consequently a growth of the COP coefficient for the entire refrigeration installation. In that way, although in a long term, the proposed project can speed-up progress in the ejector technique but also stimulate development of CO2 air-conditioning systems in mobile and stationary applications, heat pumps and refrigeration units.

Papers in scientific journals:

- Michal Haida, Michal Palacz, Jakub Bodys, Jacek Smolka, Paride Gullo, Andrzej J. Nowak; An experimental investigation of performance and instabilities of the R744 vapour compression rack equipped with a two-phase ejector based on short-term, long-term and unsteady operations, Applied Thermal Engineering, 185 (2021) 116353.

- Michal Haida, Jacek Smolka, Armin Hafner, Michal Palacz, Ziemowit Ostrowski, Jakub Bodys, Ekaterini K. Kriezi, Sven Försterling, Andrzej J. Nowak, Krzysztof Banasiak; Performance operation of liquid ejectors for a R744 integrated multi-ejector supermarket system using a hybrid ROM, International Journal of Refrigeration, 110 (2020) 58-74.

- Michal Haida, Rafal Fingas, Wojciech Szwajnoch, Jacek Smolka, Michal Palacz, Jakub Bodys, Andrzej J. Nowak; An Object-Oriented R744 Two-Phase Ejector Reduced-Order Model for Dynamic Simulations, Energies, 12 (2019) 1282.

- Jakub Bodys, Michal Palacz, Michal Haida, Jacek Smolka, Andrzej J. Nowak; Analysis of the R744 flow through the ejector ducts on the basis of visualisation procedure at the dedicated laboratory test rig, 14-th IIR Gustav Lorentzen Conference, 2020, Kyoto, Japan.

- Michal Haida, Rafal Fingas, Wojciech Szwajnoch, Jacek Smolka, Michal Palacz, Jakub Bodys, Andrzej J. Nowak; A R744 Transcritical Refrigeration Test Rig Equipped With A Transparent Two-phase Ejector For Flow Visualisation: Experimental Study, IIR Rankine 2020 Conference, 2020, Glasgow, U.K.

- Michal Haida, Rafal Fingas, Wojciech Szwajnoch, Jakub Bodys, Michal Palacz, Jacek Smolka, Andrzej J. Nowak; The R744 vapour compression test rig designed for visualisation of two-phase flow inside ejectors, 25th IIR International Congress of Refrigeration, 2019, 1 – 9, Motreal, Quebec, Canada.