Finished projects

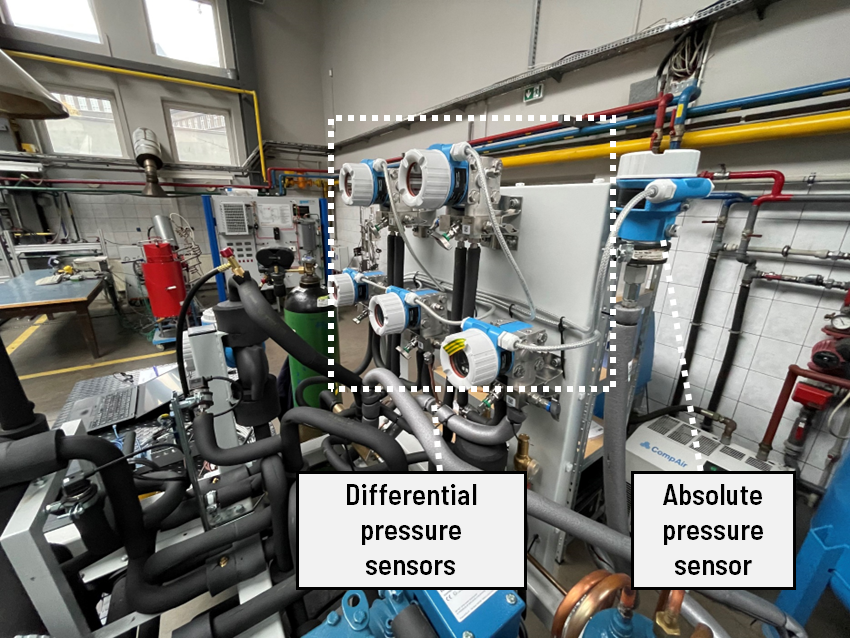

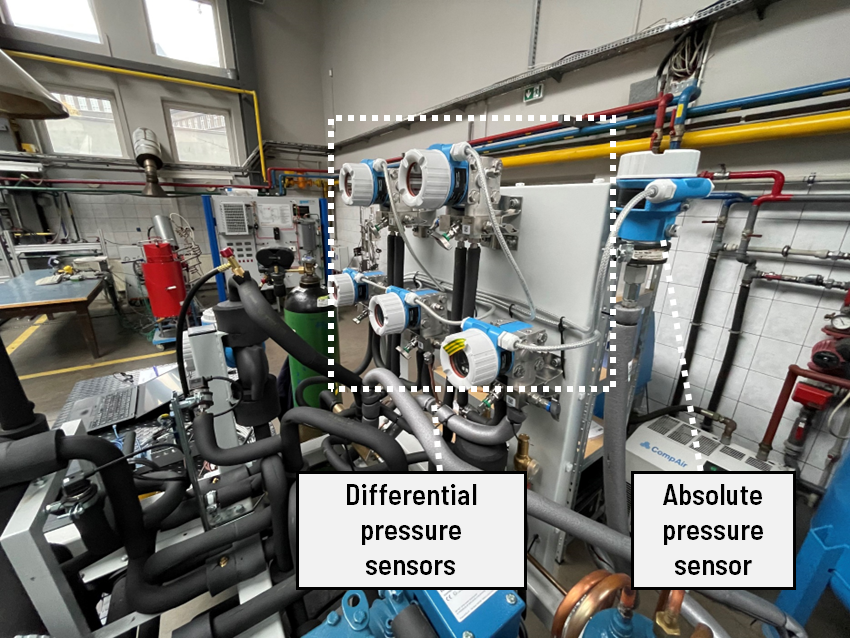

Description: The aim of the project is to test the performance of the R290 (propane) ejector with geometry adjustable by means of a needle that can be moved axially inside the motive nozzle. The tests of the ejector efficiency are performed on an experimental stand to measure also pressure, temperature and mass flow rate. The 10.0 kW propane heat pump test stand enables testing of ejectors for various applications and configurations: two-phase, liquid and gas operations.

The R290 ejector-based heat pump test rig equipped with the set of differential pressure sensors for ejector pressure drops measurements

Results:As part of the research work, a report was prepared presenting the characteristics of the regulated ejector operation with global parameters: ejector efficiency, ejection ratio, mass flows, and local parameters, i.e. pressure drops inside the device.

Collaboration: • The research work was commissioned by the Italian RICERCA SUL SISTEMA ENERGETICO – RSE S.P.A. research institute and a team of scientists from the prestigious Politecnico di Milano university.

Description: SuperSmart-Rack project was an international project funded by Research Council of Norway. The main objective of the project was to develop the next generation of CO2 refrigeration systems for supermarkets.

Results:The integrated CO2 vapour compression rack equipped with two multi-ejector modules was manufactured and installed in SINTEF/NTNU laboratory in Trondheim, Norway. The ejectorPL team developed an enhanced computational fluid dynamics model of the R744 two-phase ejector for numerical simulations in transcritical and subcritical conditions. Moreover, the innovative hybrid reduced-order model of vapour ejectors for low and high pressure lift and liquid ejectors was developed for performance mapping of ejectors installed in the multi-ejector models.

Collaboration: • SINTEF Energy Research (Norway) • Danfoss A/S (Dania) • Norwegian University of Science and Technology NTNU (Norway) (reference letter) • TLK-Thermo GmbH (Niemcy) (reference letter) • REMA 1000 (Norway) • Norgesgruppen (Norway)

Description: MultiJet project was an international project funded by Polish-Norwayn Research Fund. The main objective of the project was to commercialise the R744 supermarket system equipped with the multi-ejector module for energy performance improvement.

Results:Two R744 supermarket units equipped with the prototype multi-ejector module were installed in Trondheim, Norway and in Spiazzo, Italy. The fields measurements from both systems confirmed the system energy performance improvement during the test campaign. The ejectorPL team designed ejectors installed in the prototype multi-ejector blocks based on the developed computational fluid dynamic numerical model of the R744 two-phase ejector.

Description: R1234yf subcritical ejector design that has been subcontracted by SINTEF. In the project that was implemented in the year 2019, the role of SUT was to assist SINTEF in numerical validation of subcritical R1234yf ejectors.

Results: Designed single-phase and two-phase R1234yf ejectors.

Description: R744 subcritical ejector design that has been subcontracted by SINTEF. In the project that was implemented in the year 2019, the role of SUT was to assist SINTEF in numerical validation of subcritical R744 ejectors.

Results: Designed single-phase R744 ejector.

Description: Subcontracting in HighEFF project WP2.2 2018 that has been subcontracted by SINTEF.

Results: In the project that was implemented in the year 2018, the role of SUT was to build up a competence in heat transfer effects on a R744 ejector.

Description: R1234yf ejector design that has been subcontracted by SINTEF. In the project that was implemented in the year 2018, the role of SUT was to assist SINTEF in numerical validation of R1234yf ejectors.

Results: Design of R1234yf ejector.

Description: R744 ejector design that has been subcontracted by SINTEF. In the project that was implemented in the year 2017, the role of SUT was to assist SINTEF in numerical validation of single-phase R744 ejectors.

Results: Design of R744 ejector.

Description: CO2 HeatPumps project was an international project funded by the Polish-Norwegian Research Fund. The main objective of the project was a technological development of the small-scale heat pumping units equipped with the two-phase ejector utilising natural refrigerant R744.

Results: Benefits resulting from the potential widespread use of the system being the subject of the project are the following:

- Employing an environmentally friendly, inexpensive and easy accessible working fluid,

- Use of an ejector instead of a typical throttling valve in commercially available units.

Collaboration: SINTEF Energy Research (Norway)